Kernels of Chimaera

An RCA project exploring how bacterial-based material might be used in future manufacturing.

Bacterial packaging. Fermented clothes. Cellulose furniture. Sounds a little bit gross, doesn’t it? But according to some designers, bacterial-based material – literally harvested in a lab – might be widely used in future manufacturing.

There’s several good reasons why you might want to produce materials this way. One is that bacterial cellulose, because of its natural properties, can decompose when it's finished with. Bored of your fermented jumper? Just chuck it on a compost heap.

We saw a great project exploring this microbe-manufacturing future at the RCA graduate show a couple of weeks ago. The Kernels of Chimaera, created by Design Interactions student Stefan Schwabe, investigated how a factory that produces living materials – in this case, bacterial cellulose – might work.

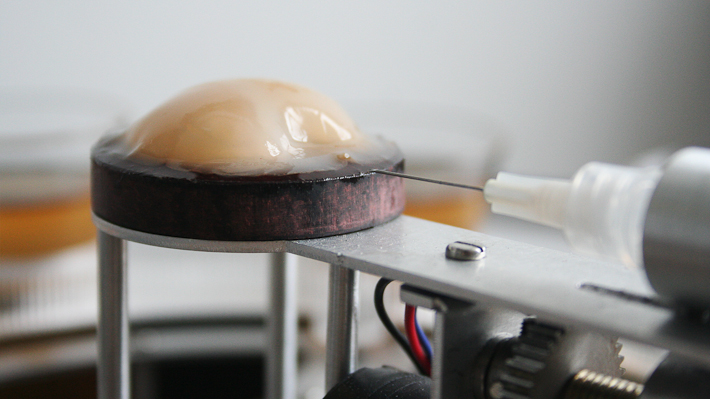

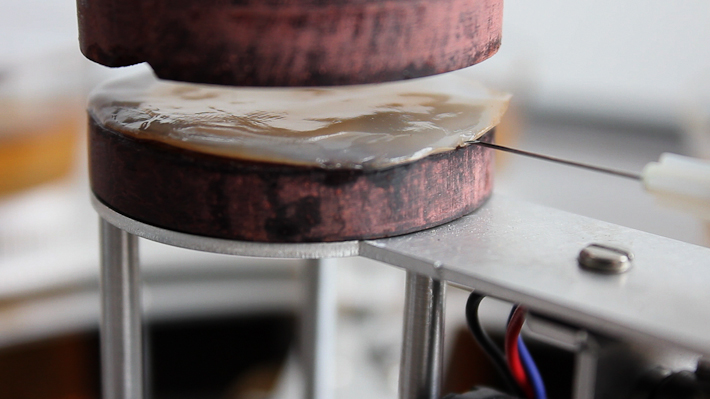

The whole process is completely automated. Each day a new layer of cellulose is produced inside what Schwabe calls a ‘reactor jar’. This jelly-like material is then slowly picked up by a vacuum arm and dropped back down within a small wooden clamp. A syringe then enters the material and gently blows air into it, turning the cellulose into a three-dimensional shape. The new wet material is then dried out with air and finally projected up into the air to float.

The process is executed brilliantly and got us thinking about how bacterial material manufacturing might be realised in the future. Have watch of the video above to see how it all works.

Discussion