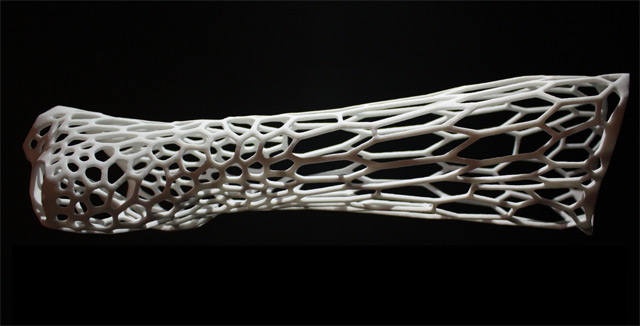

A broken arm means more than an initial excruciating pain. There’s the bulky, itchy cast that follows, sometimes for months on end. While collecting signatures from friends can be fun, it certainly doesn’t make up for the sticky, sweaty situation wrapped around an arm or wrist. In response to this, Jake Evill, a graduate from the Architecture and Design School at Victoria University of Wellington in New Zealand, designed Cortex, a conceptual 3D printing exoskeletal cast.

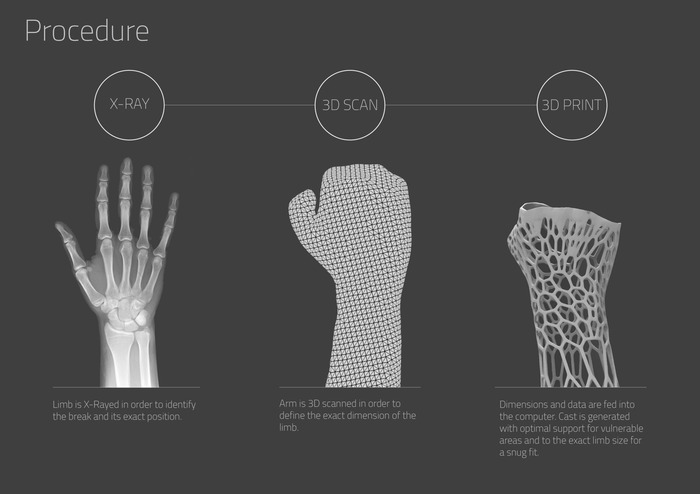

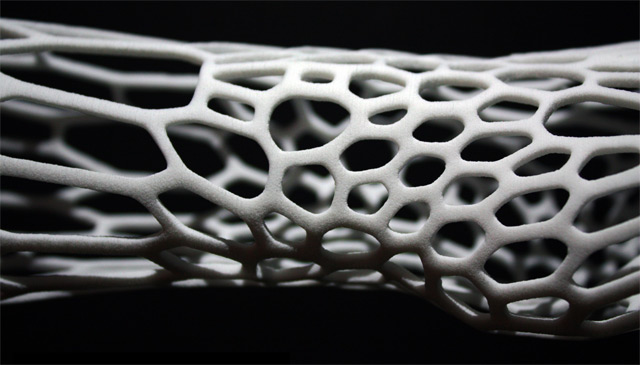

Aside from being far less ugly than a conventional cast, Cortex offers a practical and more comfortable solution to a fractured bone. An X-Ray is taken to identify the break and its exact position and the arm is then 3D scanned in order to define the exact dimension of the limb. The dimensions and data are fed into a computer and a cast is generated with optimal support for vulnerable areas and to exact limb size for snug fit. One side of cast opens to enable access and once fitted, it snaps closed with built-in durable fasteners. Cortex is thin, but it's durable. Perhaps it’s most admirable feature is that it remains ventilated and washable, reducing hours spent aiming for that unreachable itch with a pencil or covering a cast with a plastic bag to shower.

The only downside is cost. While Cortex, according to Evill, “provides a highly technical and trauma zone localized support system that is fully ventilated, super light, shower friendly, hygienic, recyclable and stylish” it is a bit cost prohibitive at the moment. Hopefully, this will change and this stylish relief can be felt by all, in the unfortunate event of a broken bone of course.

Discussion